Prototyping technologies have revolutionized the automotive development process, providing engineers and designers with powerful tools to streamline and enhance their work. These technologies enable the creation of physical prototypes that accurately represent the final product, allowing for comprehensive evaluation and testing before mass production. By simulating real-world conditions and functionalities, prototyping technologies enable automotive manufacturers to address design flaws, optimize performance, and ensure customer satisfaction.

Benefits of Prototyping Technologies for Automotive Development

Enhancing Design Efficiency and Flexibility

One of the key benefits of using prototyping technologies in automotive development is the enhancement of design efficiency and flexibility. Traditionally, the design process involved multiple iterations and modifications, which were time-consuming and costly. With the advent of prototyping technologies, designers can rapidly create physical prototypes and evaluate their performance in various scenarios. This iterative approach allows for quick adjustments and improvements, resulting in a more efficient and flexible design process.

- Prototyping technologies enable designers to visualize their ideas and identify potential design flaws early in the development process.

- By creating physical prototypes, designers can assess the ergonomics and aesthetics of the vehicle, ensuring optimal user experience.

- Prototyping technologies also facilitate collaboration among different stakeholders, such as engineers, designers, and manufacturing teams, fostering a more iterative and inclusive design process.

Reducing Development Time and Costs

In the automotive industry, time-to-market is a critical factor for success. Prototyping technologies significantly reduce development time and costs, enabling manufacturers to bring new vehicles to market faster and at a lower cost. By using rapid prototyping techniques, such as 3D printing, automotive companies can quickly fabricate parts and components, eliminating the need for expensive tooling and molds.

- Rapid prototyping technologies, such as 3D printing, allow for faster production of prototypes and parts, reducing the overall development time.

- By eliminating the need for costly tooling and molds, prototyping technologies help automotive companies reduce manufacturing costs.

- Time and cost savings achieved through prototyping technologies enable manufacturers to invest more resources in research and development, innovation, and enhancing the overall quality of the final product.

Facilitating Early Detection of Design Flaws

Another significant advantage of prototyping technologies in automotive development is the early detection of design flaws. By creating physical prototypes, engineers and designers can assess the functionality and performance of different vehicle systems, identify potential issues, and make necessary adjustments before mass production. This early detection and resolution of design flaws result in improved product reliability, durability, and safety.

- Physical prototypes allow engineers to conduct comprehensive testing, including crash simulations, aerodynamic assessments, and performance evaluations.

- By identifying design flaws early, automotive companies can avoid costly recalls and repairs, ensuring customer satisfaction and brand reputation.

- Prototyping technologies also enable the testing of alternative designs and materials, promoting innovation and optimization of vehicle performance.

Key Prototyping Technologies Driving Change in Auto Manufacturing

Several prototyping technologies have emerged as major drivers of change in the automotive manufacturing industry, revolutionizing the way vehicles are designed, developed, and produced.

- Virtual and Augmented Reality (VR/AR): VR/AR technologies enable designers and engineers to create immersive virtual environments that simulate real-world driving conditions and vehicle interactions. This allows for comprehensive evaluation and optimization of design elements, such as ergonomics, visibility, and driver experience.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms can analyze vast amounts of data collected from sensors and simulations, helping designers and engineers make informed decisions. These technologies enable predictive modeling, optimization of vehicle performance, and identification of potential design flaws.

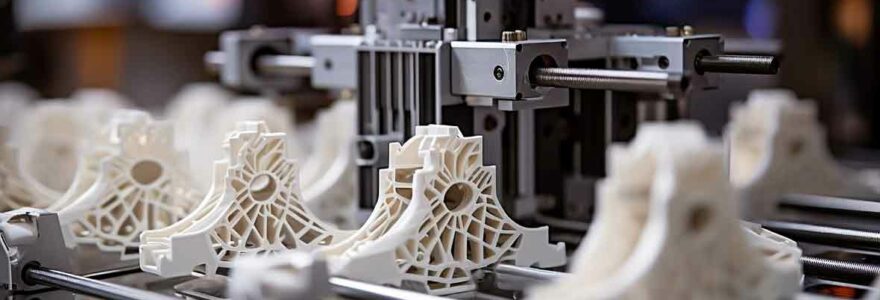

- 3D Printing: The growth of 3D printing has revolutionized automotive prototyping by allowing for the rapid production of complex parts and components. This technology enables manufacturers to reduce costs, improve design flexibility, and achieve faster time-to-market.

The Potential for Virtual and Augmented Reality in Prototyping

The potential of virtual and augmented reality in automotive prototyping is vast and continues to expand. With ever-improving VR/AR technologies, automotive designers and engineers can create highly realistic simulations that mimic real-world driving experiences. These simulations enable comprehensive evaluation and optimization of vehicle designs, enhancing safety, ergonomics, and overall user experience.

Influence of Artificial Intelligence and Machine Learning on Automotive Prototyping

The influence of AI and ML on automotive prototyping is transformative. By leveraging these technologies, automotive manufacturers can analyze vast amounts of data and make data-driven decisions throughout the design and development process. AI and ML algorithms can optimize vehicle performance, identify potential design flaws, and enhance overall product reliability and safety.

Growth of 3D Printing and Its Impact on Future Automotive Prototyping

The growth of 3D printing has revolutionized automotive prototyping, and its impact will continue to shape the future of the industry. With advancements in 3D printing technologies, automotive manufacturers can quickly produce complex parts and components, reducing development time and costs. This technology also promotes design flexibility, customization options, and the use of innovative materials, further enhancing the efficiency and effectiveness of automotive prototyping.